In the world of manufacturing, digital transformation isn’t just a buzzword—it’s essential for survival and growth. But it’s not merely about upgrading your tech stack or installing the latest software. True digital transformation means fundamentally rethinking your company’s mission, values, and culture, all starting with a strong commitment from leadership.

Digital transformation goes beyond the pursuit of operational efficiency. It’s a comprehensive reimagining of how your business functions, demanding a mindset shift at every level and wholehearted support from everyone involved. It’s a collective journey that brings people, data, and processes into alignment, building a unified vision for the future.

The heart of real change isn’t just in adopting new tools—it’s in nurturing a culture that values innovation, welcomes change, and is always looking for ways to improve. The most successful transformations blend the human element with the latest technology, making your business more agile, responsive, and focused on the customer.

Digital transformation means weaving technology and data into every part of your operations. It’s a long-term commitment to using information and automation to enhance customer experience, boost manufacturing efficiency, and keep your competitive edge in a digital-first world.

Achieving digital maturity is a journey, not a sprint. It unfolds in phases, each step shaped by your company’s unique needs and current digital strengths. With each phase, you strengthen your digital mindset, encourage innovation, and unlock real business value. The journey takes patience and persistence, but the rewards—greater efficiency, higher customer satisfaction, and long-term competitiveness—make it well worth the effort.

As you continue on this path, remember: digital transformation is not a one-off project but an ongoing process of learning and adaptation. By fostering a culture of continuous improvement, your organisation can thrive in the ever-changing world of modern manufacturing and set the foundation for sustained success and resilience.

The term Industry 4.0 has become integral to discussions surrounding the future of manufacturing, representing the fourth industrial revolution that commenced approximately around 2010.

In Industry 4.0, data takes centre stage. Unlike the automation-centric focus of Industry 3.0, Industry 4.0 represents a paradigm shift by leveraging data as actionable information, thereby automating business processes.

Industry 4.0 envisions a seamless, interconnected network where data drives intelligent, automated business processes.

The transformation goes beyond automated factories; it seeks to create interconnected, intelligent systems that adapt dynamically to changing market conditions.

Embracing Industry 4.0 demands not only the adoption of advanced technologies but also the cultivation of a culture marked by innovation, adaptability, and continuous improvement. It represents a revolutionary departure from traditional manufacturing, placing businesses at the forefront of the evolving digital era.

At the core of Industry 4.0 lies the transformative force of the Industrial Internet of Things (IIoT). Functioning as a connected ecosystem, IIoT plays a pivotal role in providing users with real-time information, establishing itself as a dynamic conduit for data transformation.

When seamlessly integrated with Digital Transformation, a potent synergy materializes, giving rise to the concept of a Digital Factory. This evolved paradigm represents a sophisticated and intelligent business model that transcends traditional manufacturing frameworks.

Within the Digital Factory, data is not just accumulated but becomes a strategic asset, driving informed decision-making processes.

The harmonious amalgamation of IIoT and Digital Transformation not only ushers in a new era of operational efficiency but also fosters an environment where data evolves into actionable insights, propelling businesses toward heightened adaptability and competitiveness in the digital landscape.

What is DT?

Digital Transformation is:

What is IIoT?

Industrial Internet of Things is:

What is DF?

A Digital Factory is:

The path to Industry 4.0

To embark on the Industry 4.0 journey, businesses must follow these three strategic steps:

Step1: Perform Digital Transformation Maturity Assessment

Step2: Becoming a smarter business - take data, turn it into information and make better decisions

Step3: Plugin your newly created smart business into a digital supply chain

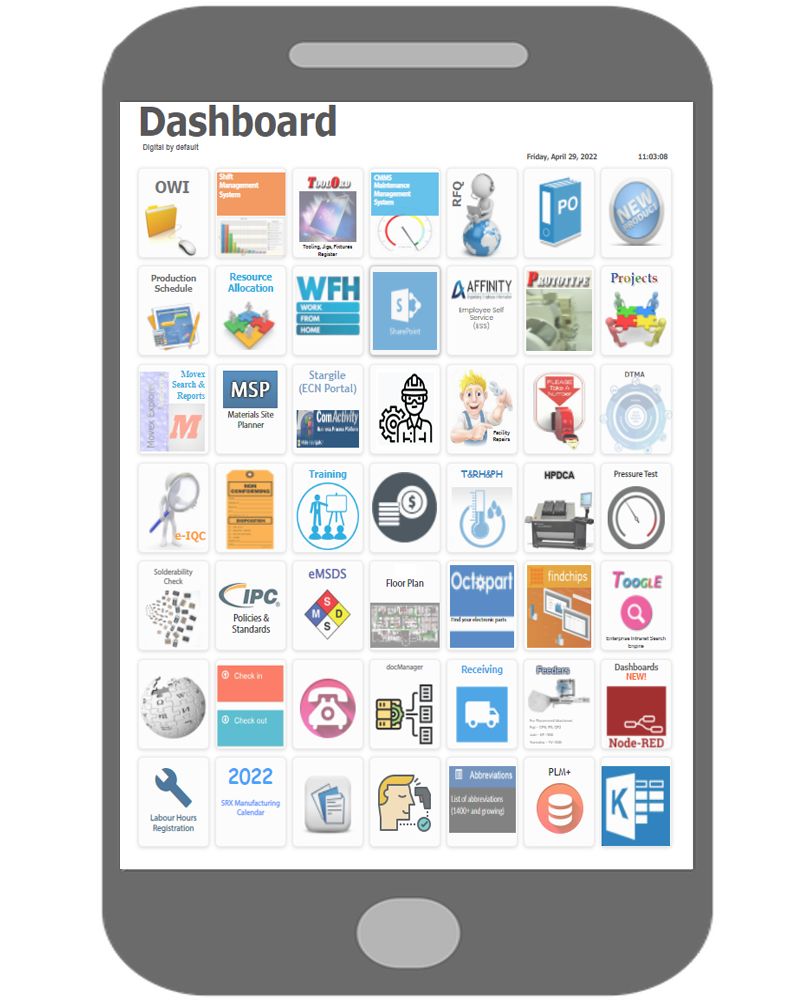

Get your smartphone for businesses,

the unified namespace,

the single source of truth