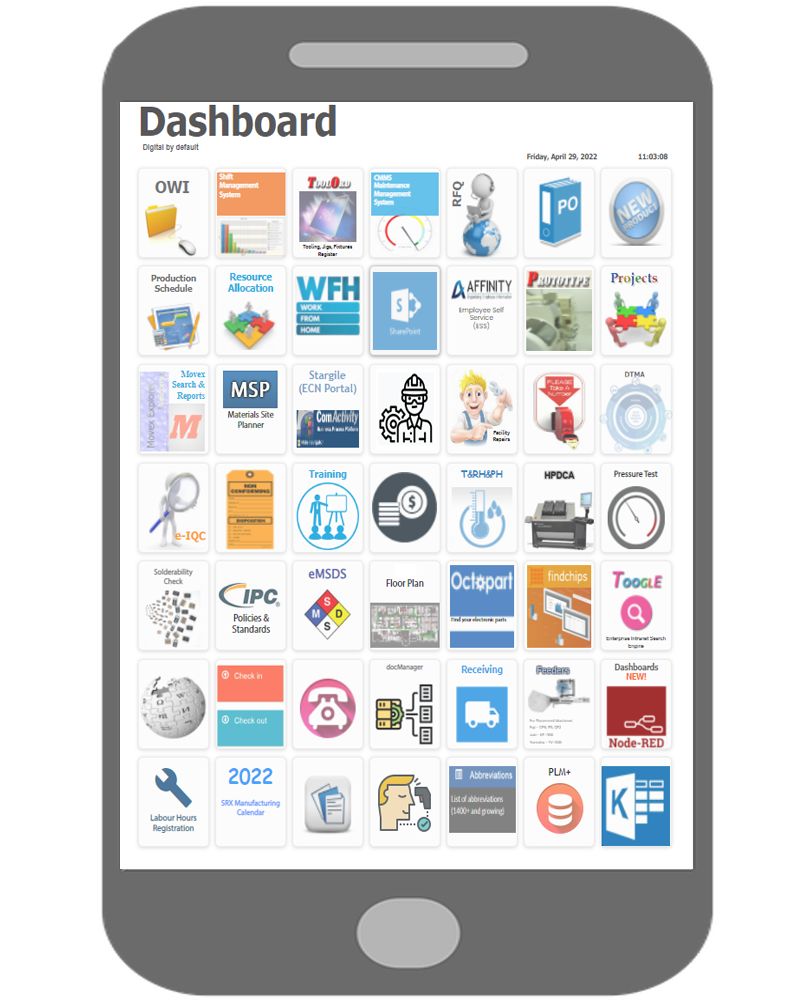

Digital by Default

Industry 4.0 represents the fourth industrial revolution. Unlike the automation-centric focus of Industry 3.0, Industry 4.0 leverages data as actionable information, automating business processes and creating seamless, interconnected networks where data drives intelligent systems.

The Power of IIoT & Digital Factory

At the core of Industry 4.0 lies the transformative force of the Industrial Internet of Things (IIoT). Functioning as a connected ecosystem, IIoT provides users with real-time information, establishing itself as a dynamic conduit for data transformation.

When seamlessly integrated with Digital Transformation, a potent synergy materialises, giving rise to the concept of a Digital Factory - a sophisticated and intelligent business model that transcends traditional manufacturing frameworks.

- Data becomes a strategic asset driving decisions

- Actionable insights from real-time information

- Heightened adaptability and competitiveness