Product Screenshots

Click any image to enlarge

AQL-based incoming quality control for raw materials and components. Catch defects before they enter production, track supplier quality, and maintain ISO 9001 compliance.

The cheapest defect is the one you never let into production. NS-eIQC provides structured incoming inspection using AQL sampling plans, ensuring consistent quality control and supplier accountability.

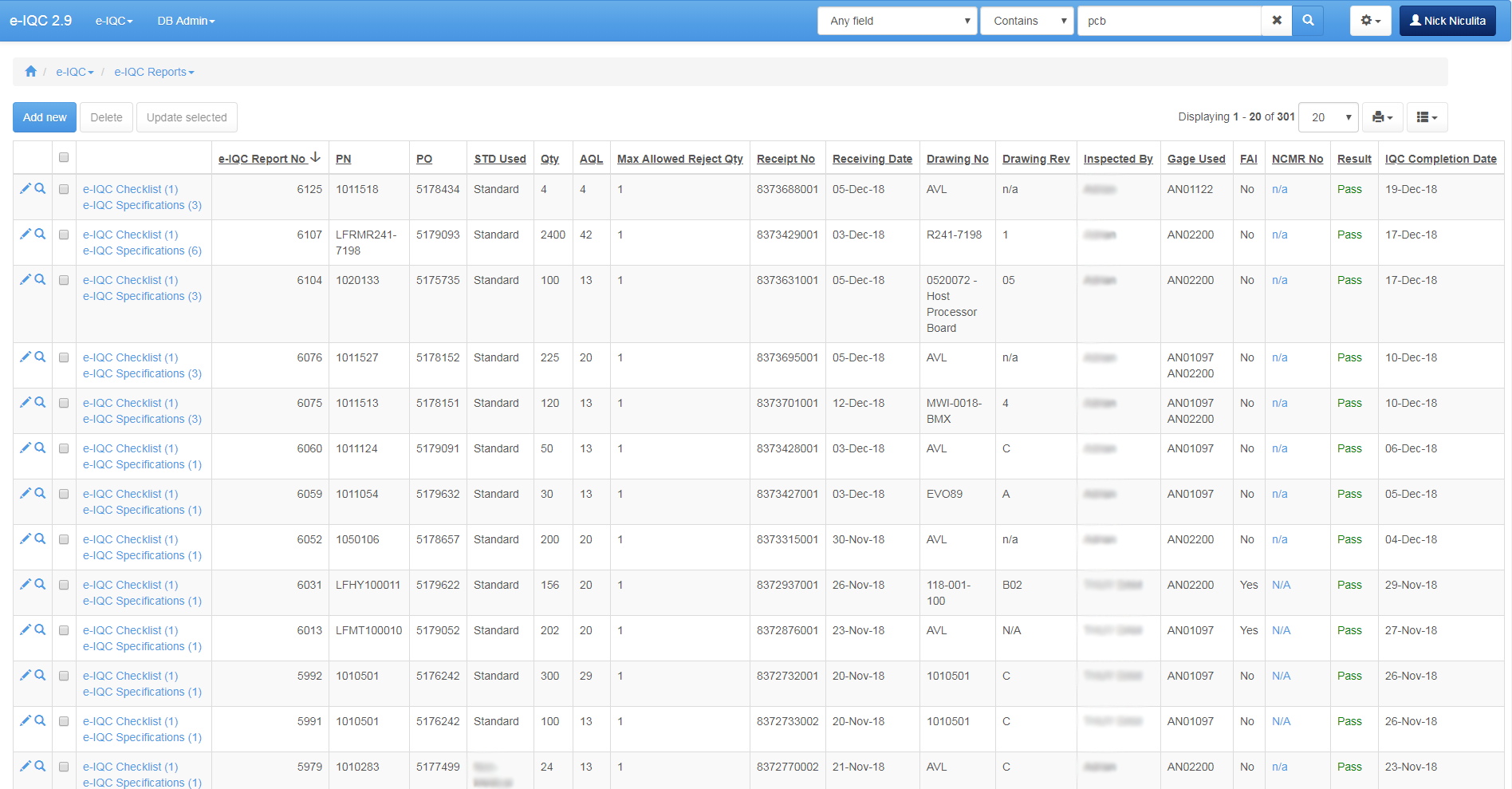

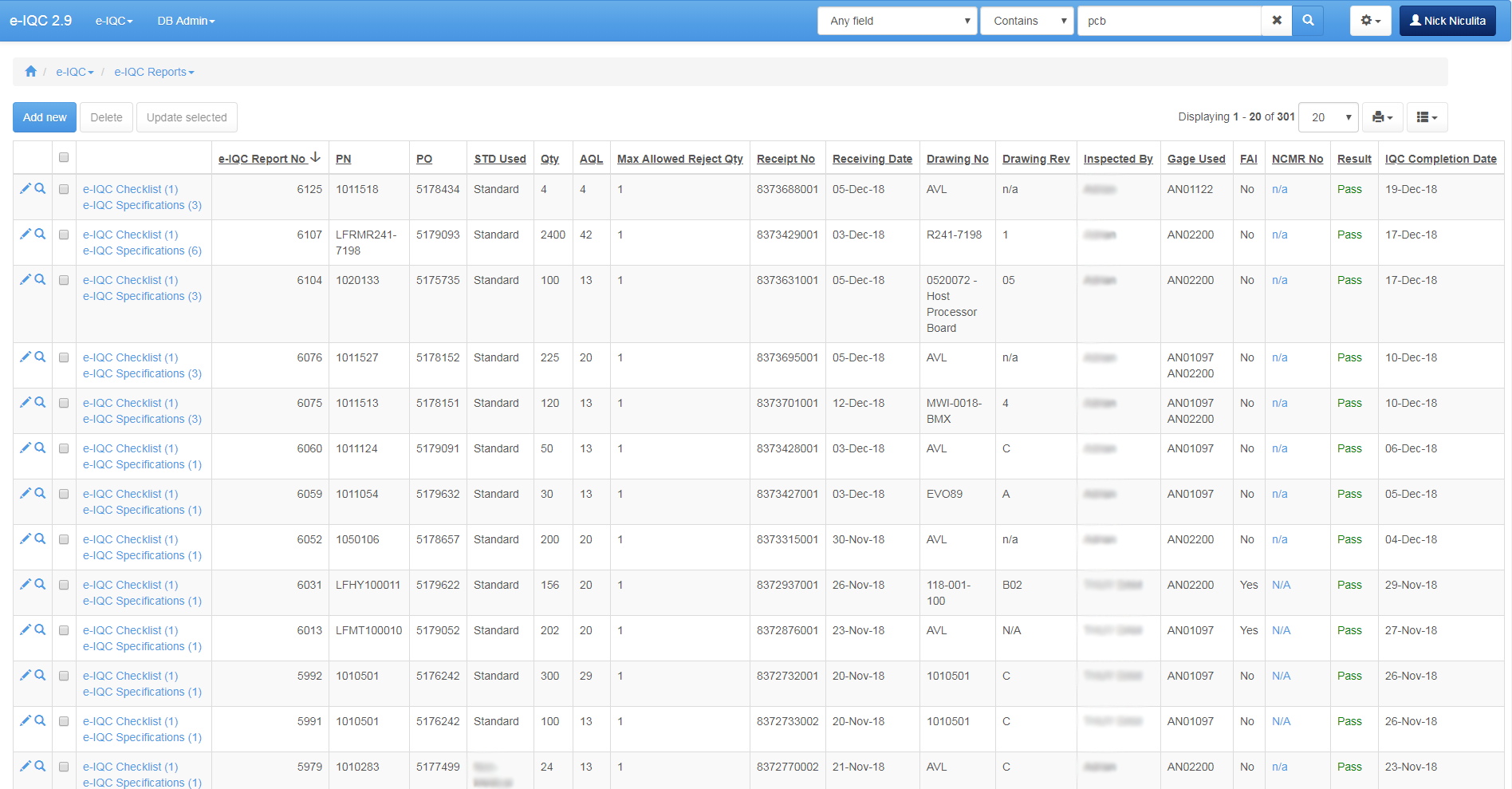

Built-in AQL tables determine sample sizes automatically. Normal, tightened, and reduced inspection levels.

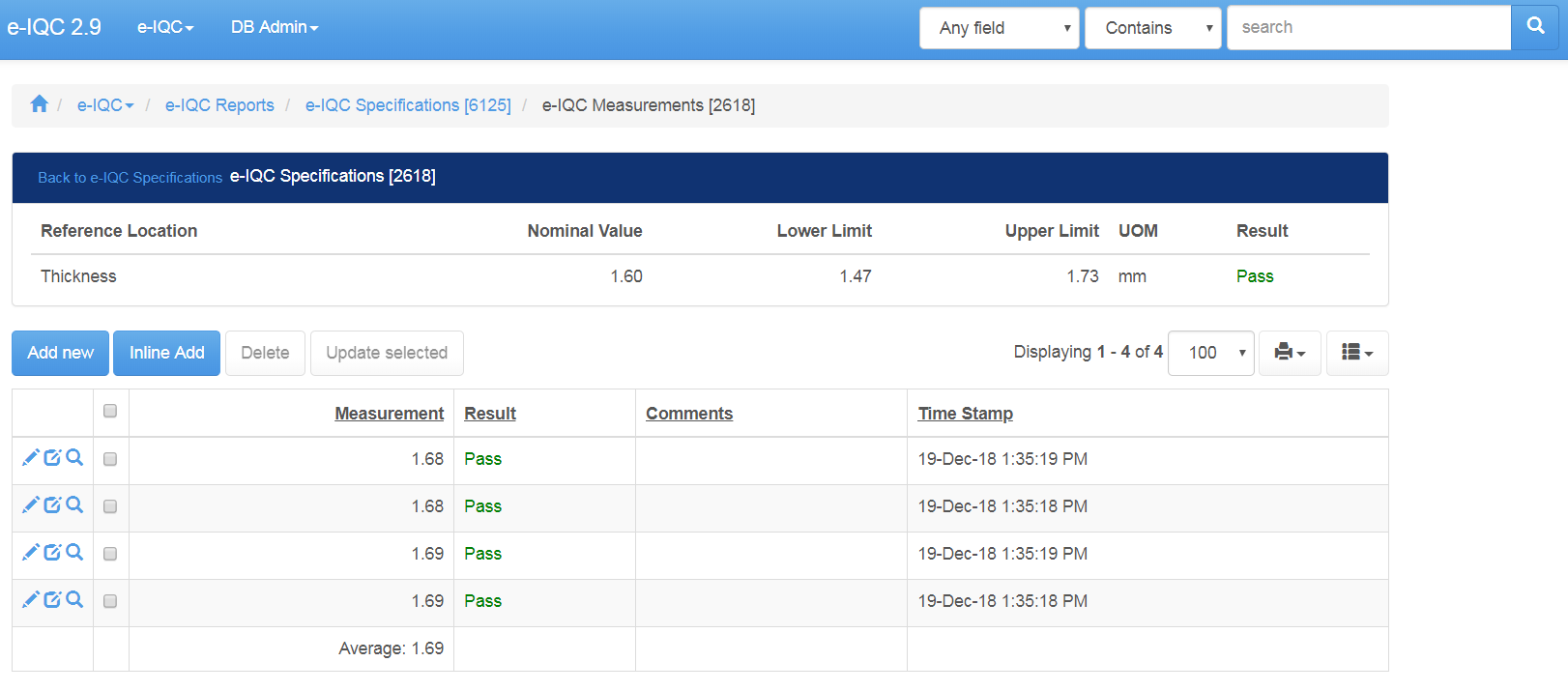

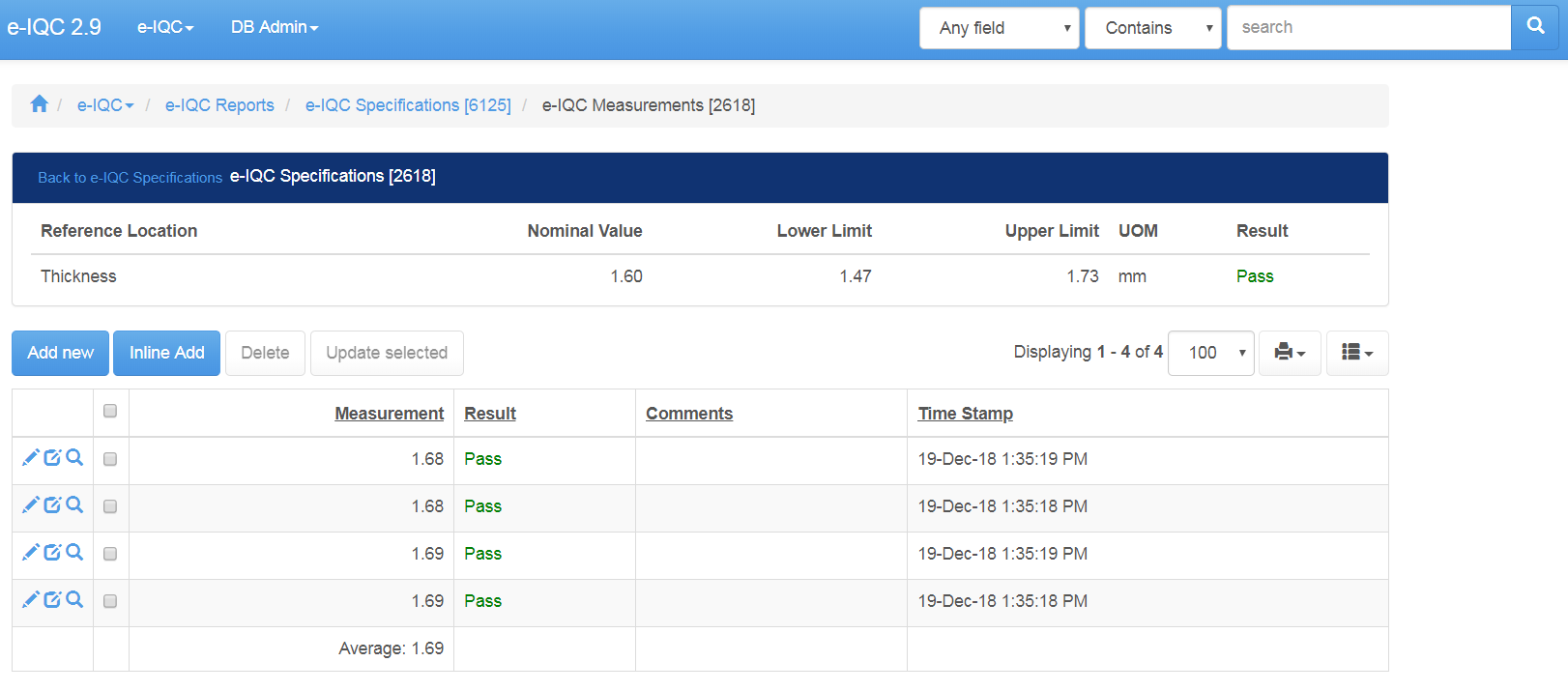

Create custom checklists per part number. Dimensional, visual, and functional checks.

Attach photos of defects directly to inspection records. Visual evidence for supplier discussions.

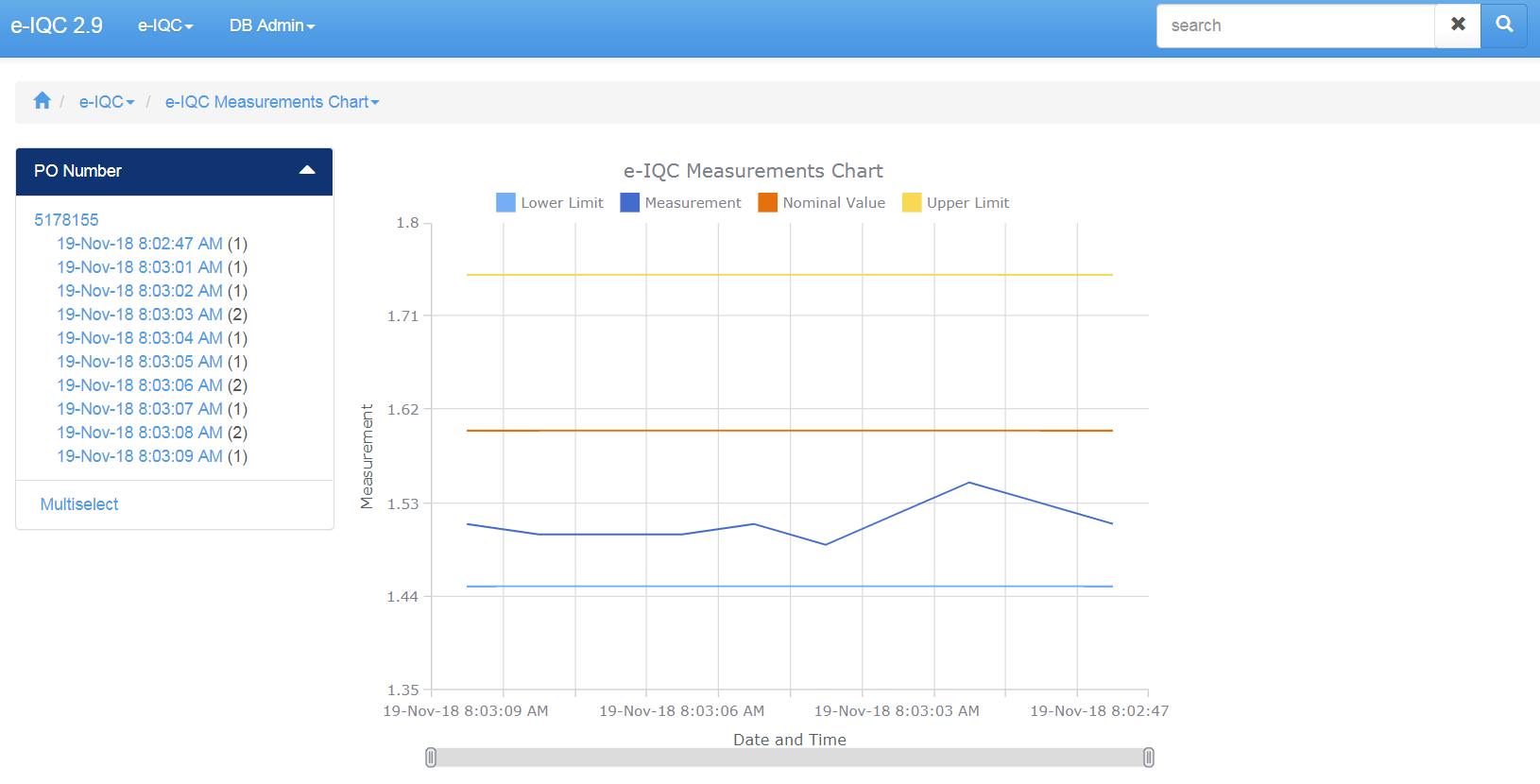

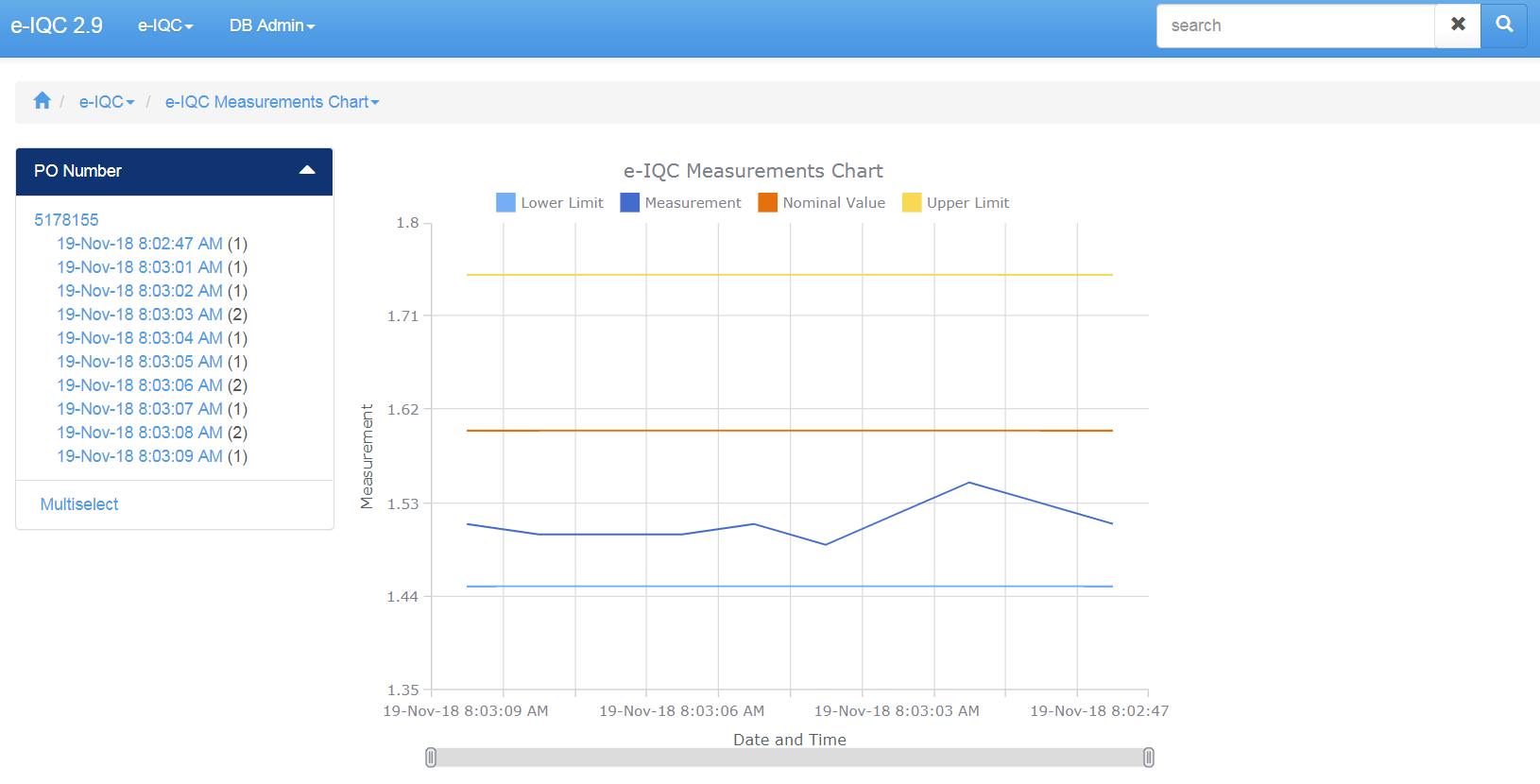

Visual charts showing incoming quality trends by supplier, part, and time period.

Track supplier quality performance over time. Generate reports for supplier reviews.

Export to Excel, CSV, and PDF. Generate inspection reports for management review.

Acceptance Quality Limit (AQL) is the maximum percentage of defective units that can be considered acceptable when sampling a batch. NS-eIQC uses international AQL tables (ISO 2859 / AS 1199) to determine the right sample size for your lot.

By using statistical sampling, you get confidence in your quality decisions without inspecting every single item - saving time while maintaining standards.

Standard sampling level for ongoing production. Switch from normal when supplier quality changes.

Increased sampling when quality deteriorates. More stringent accept/reject criteria.

Smaller samples for proven suppliers with excellent track records. Saves inspection time.

Clause 8.6 - Release of products and services. Document inspection results for compliance.

Medical device incoming inspection requirements with documented evidence.

Aerospace quality management with receiving inspection documentation.

Click any image to enlarge

The cost of catching a defect at goods-in is a fraction of finding it during production or at customer delivery.