Product Screenshots

Click any image to enlarge

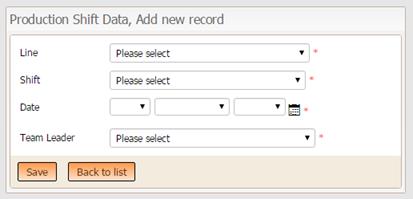

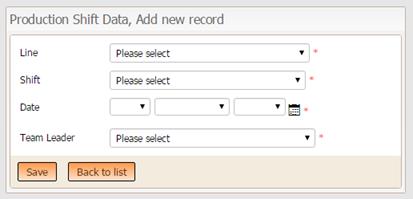

Capture everything that happens on each shift - downtime, quality issues, output, manning, material shortages. Turn shift data into actionable insights with Pareto charts and dashboards.

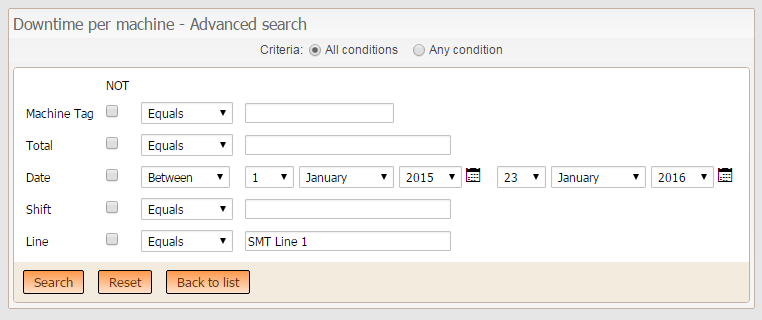

Paper shift logs get lost, can't be searched, and never get analysed. NS-SMS captures shift information digitally, making it searchable, reportable, and actionable. See patterns, identify root causes, and drive continuous improvement.

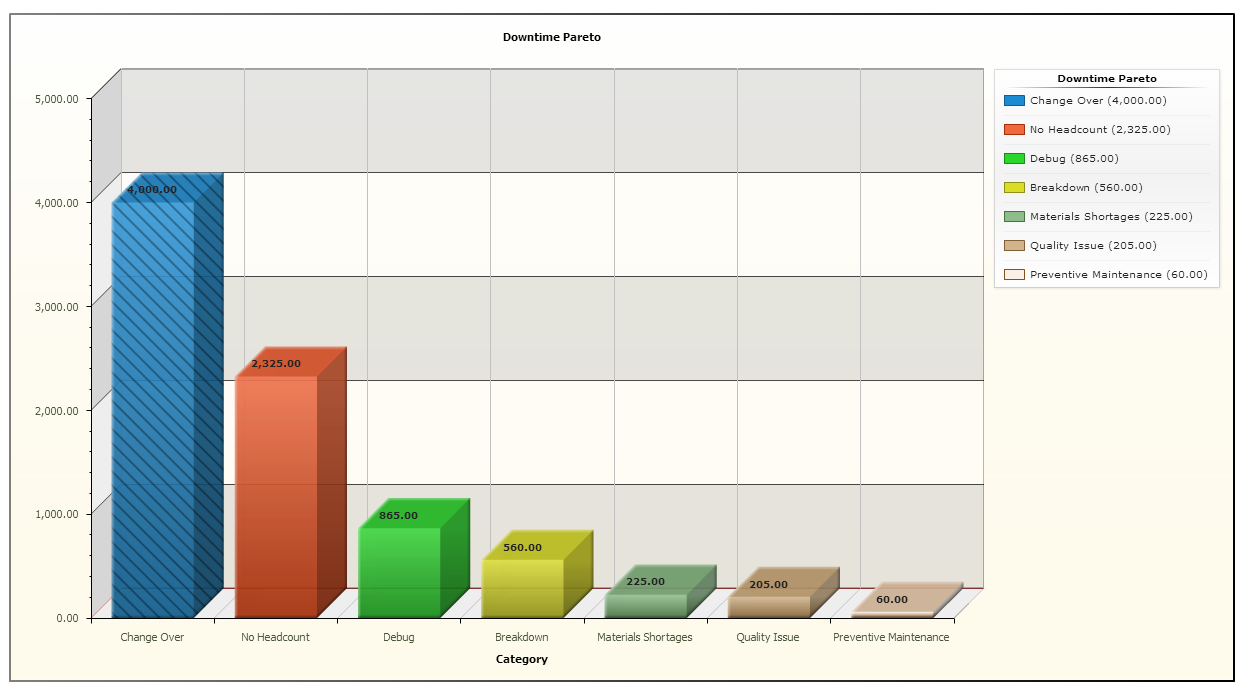

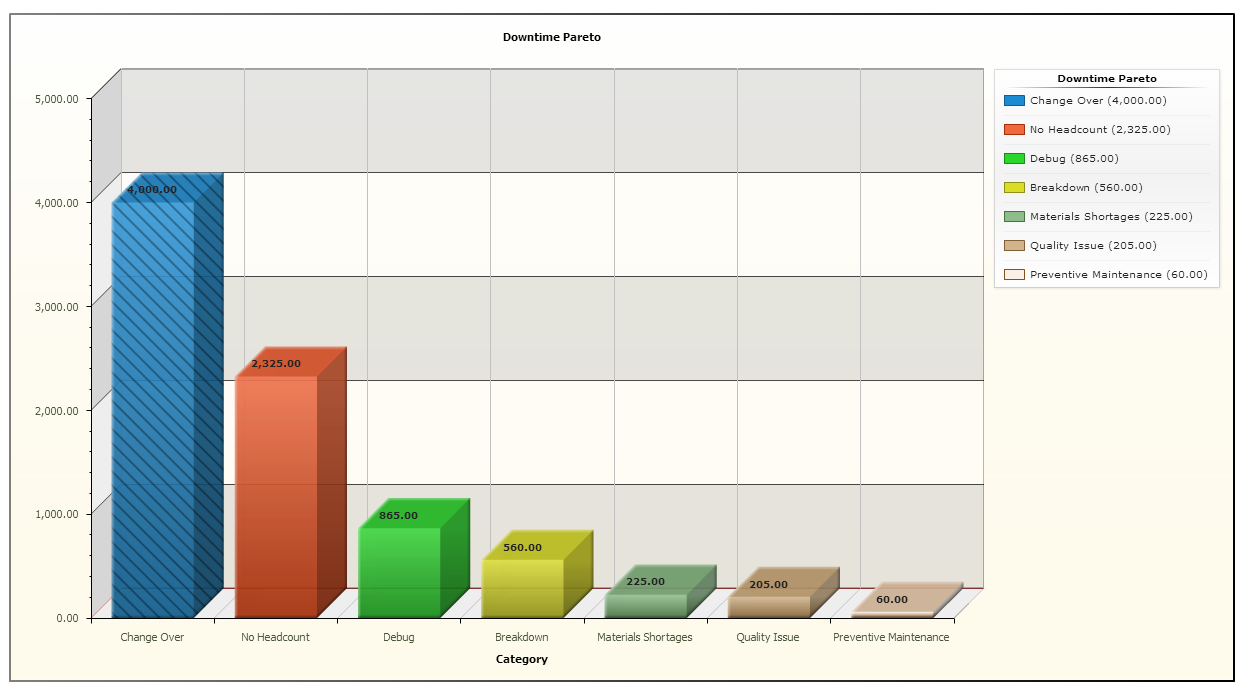

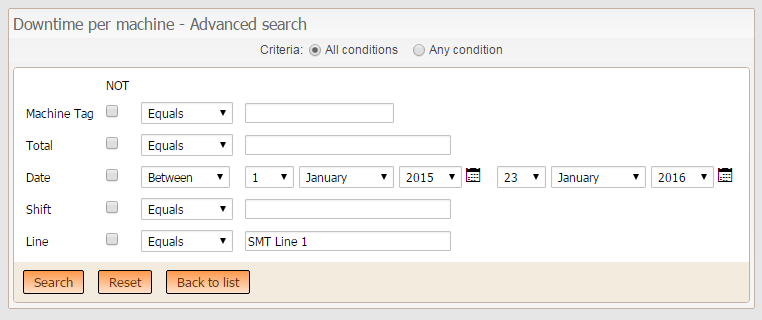

Record every stoppage with start time, duration, category, and root cause. See which issues cost you the most production time.

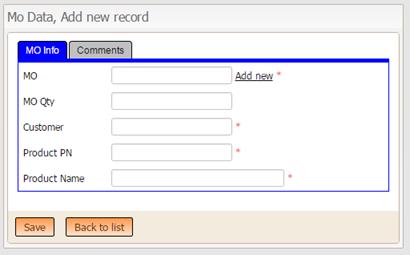

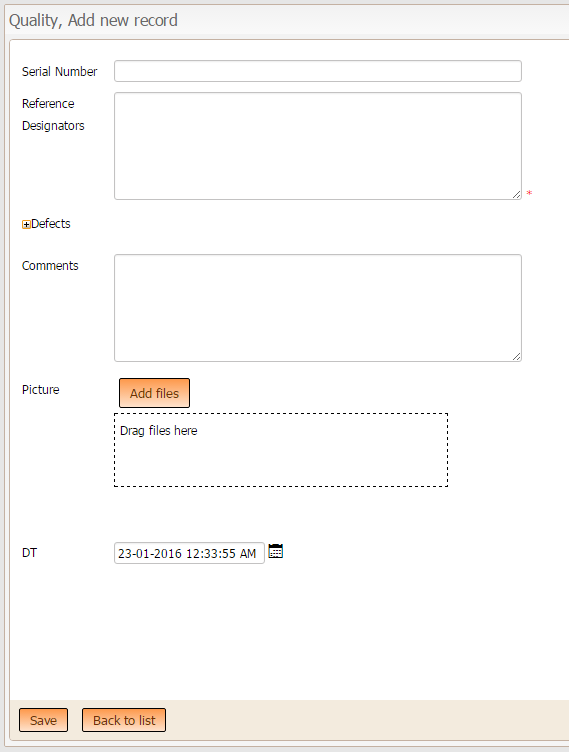

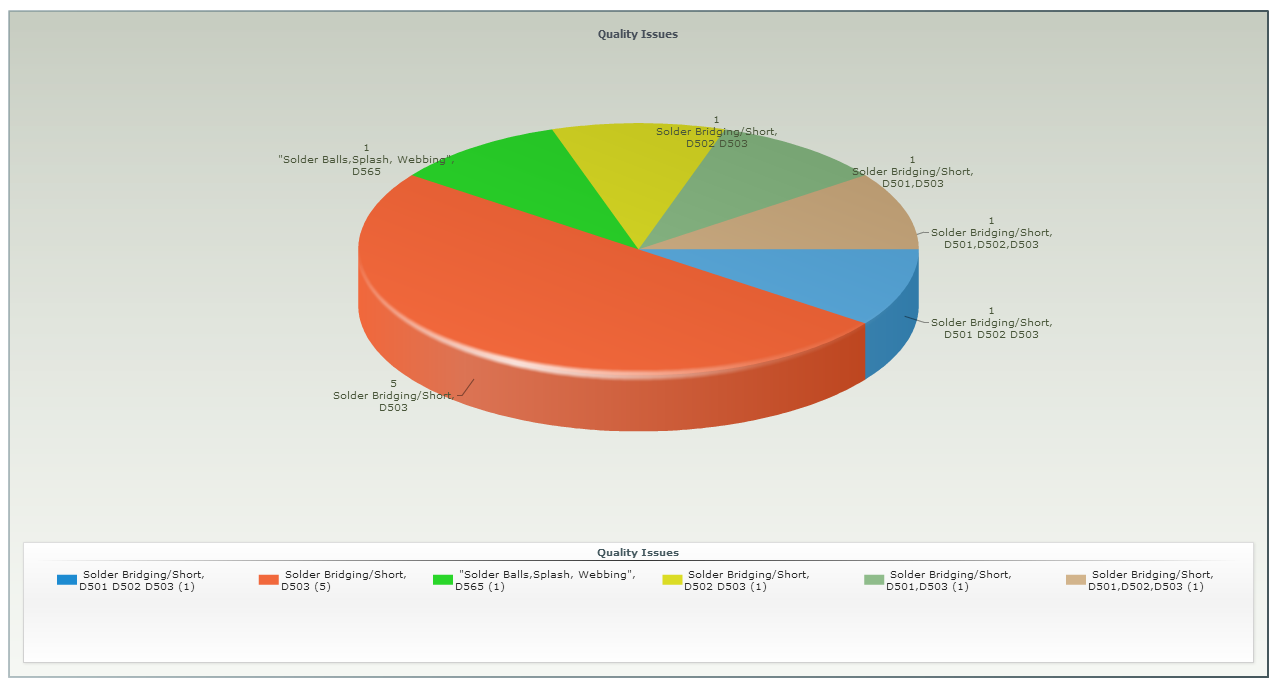

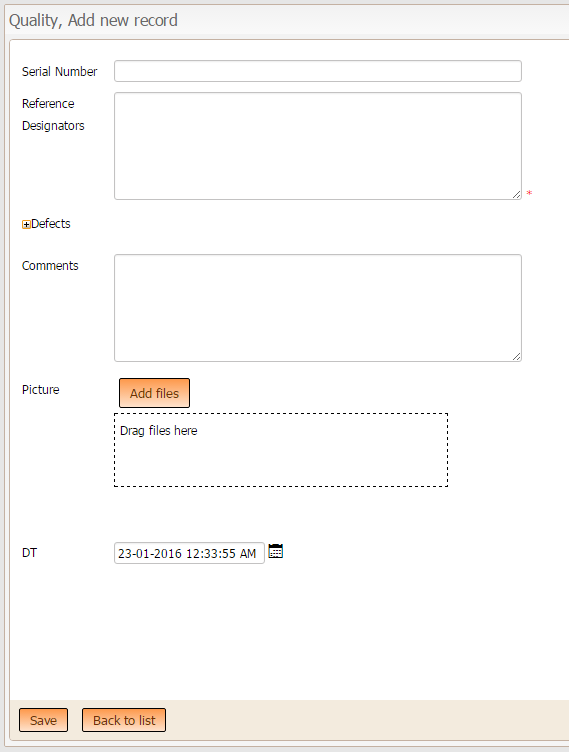

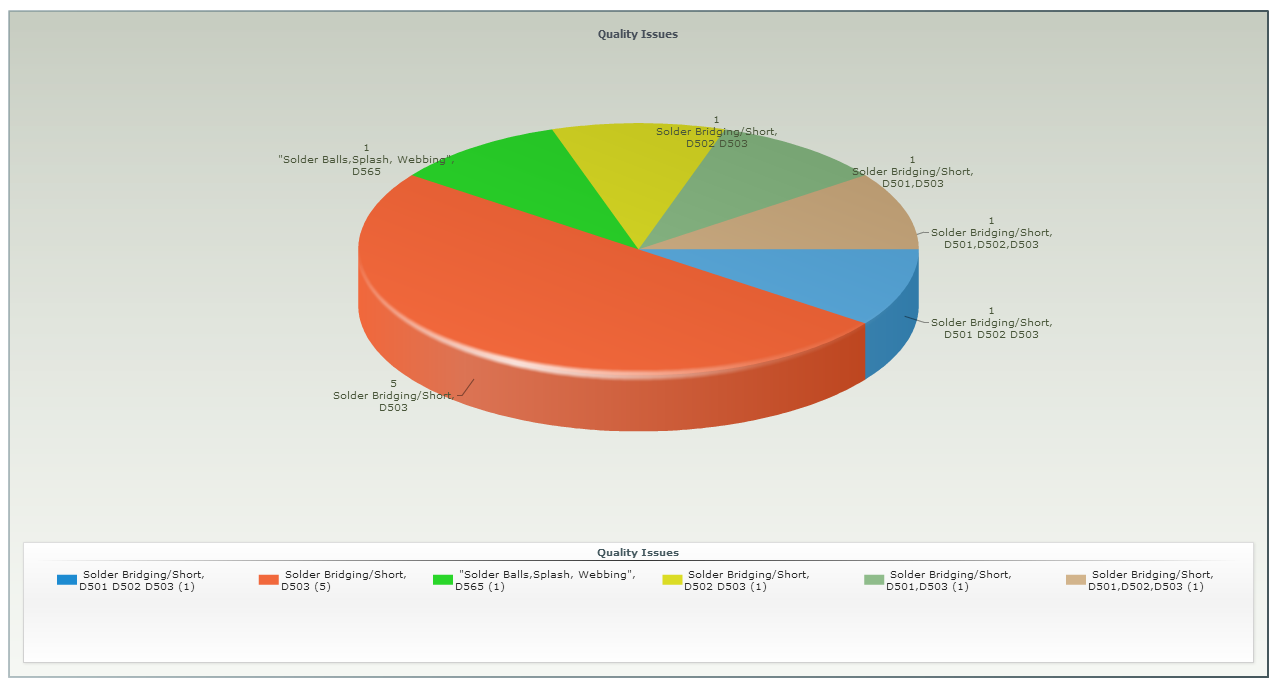

Log quality problems with photos and details. Track first article inspection, defects, and rework requirements.

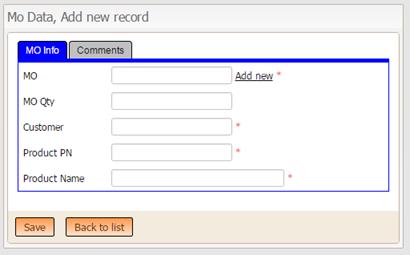

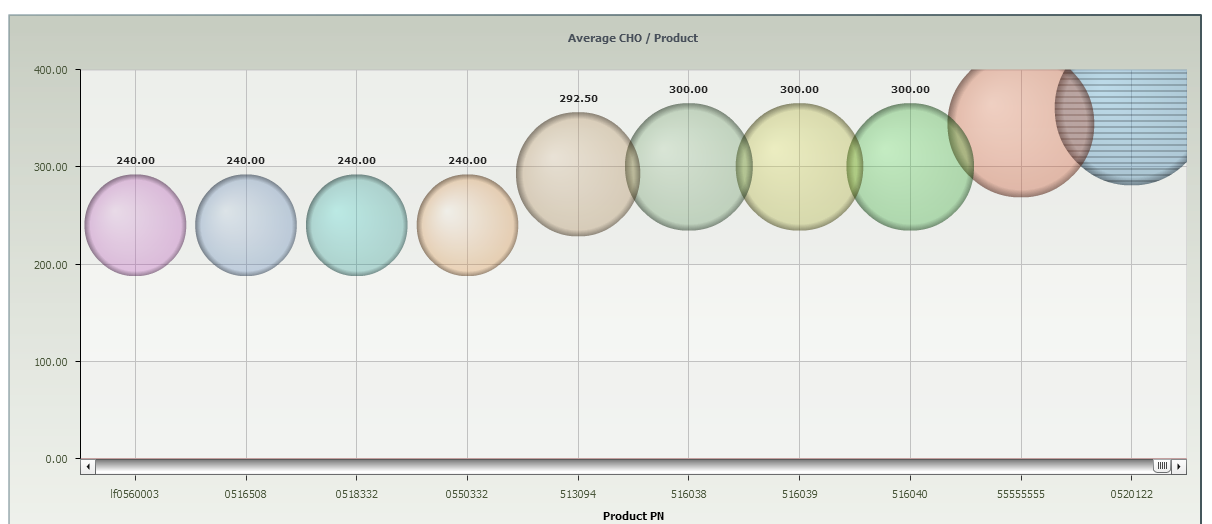

Record units produced, target vs actual, and efficiency metrics. Compare performance across shifts and lines.

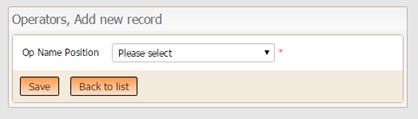

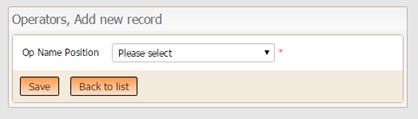

Track operator assignments, absences, and training status. Know who was on each station every shift.

Record when production stops due to missing materials. Track impact and communicate with planning.

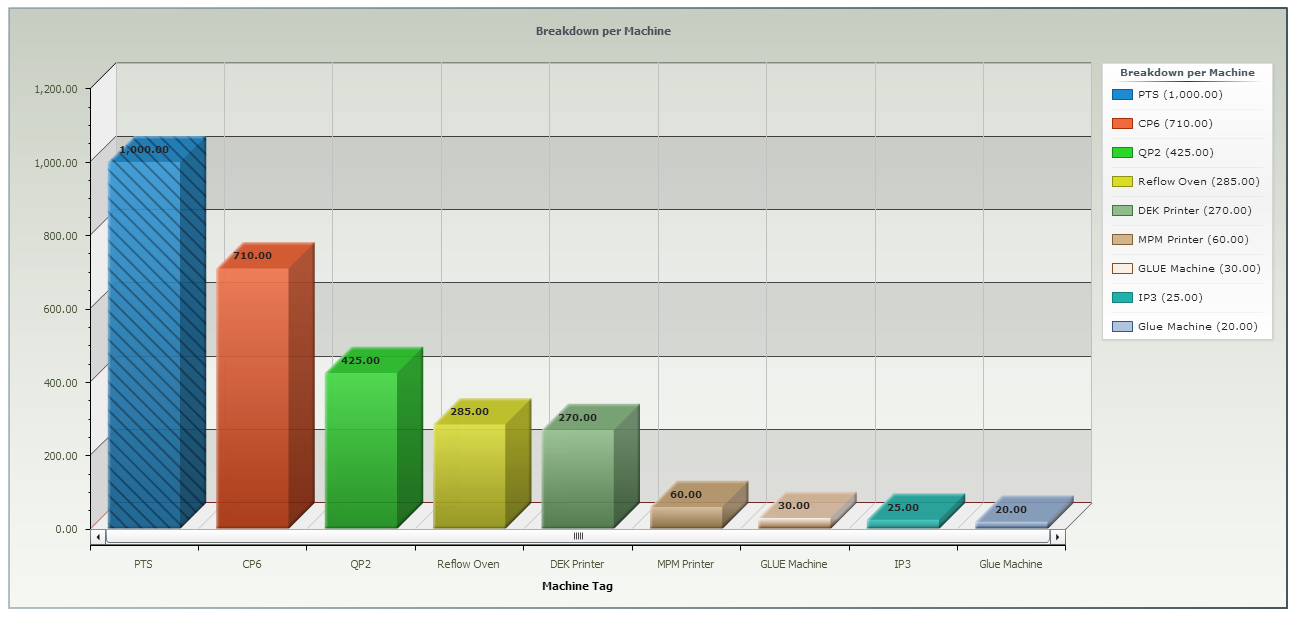

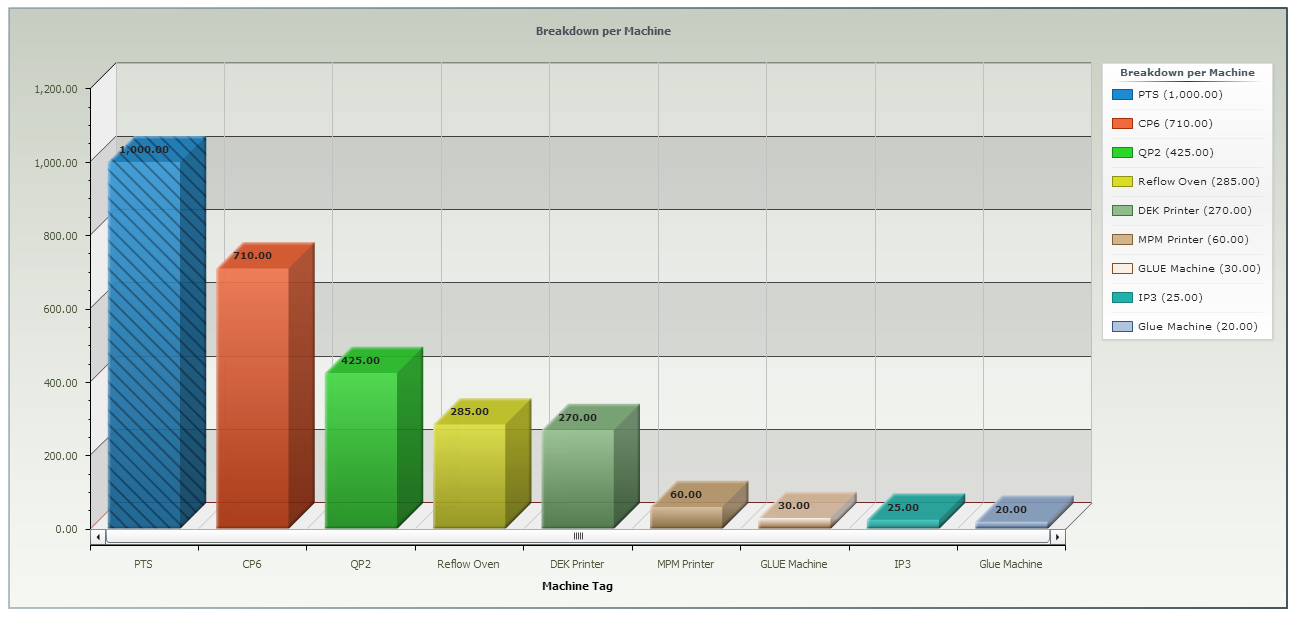

Log equipment failures with details for maintenance. Integrates with NS-CMMS for work order creation.

See top downtime causes ranked by impact

Track metrics over time to spot patterns

Compare performance across shifts and teams

Availability, Performance, Quality metrics

Current shift status visible to management

PDF and Excel export for presentations

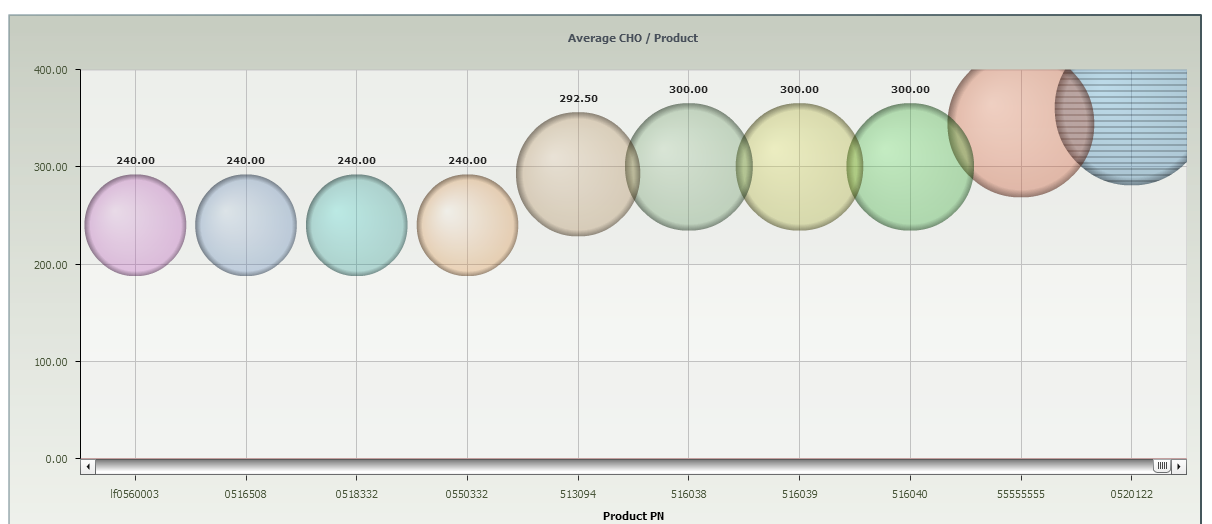

Visualise multi-dimensional data

Build reports for your specific needs

NS-SMS comes with standard manufacturing downtime categories, customisable to match your operations.

Click any image to enlarge

Stop guessing and start measuring. NS-SMS reveals the hidden losses in your manufacturing operation.