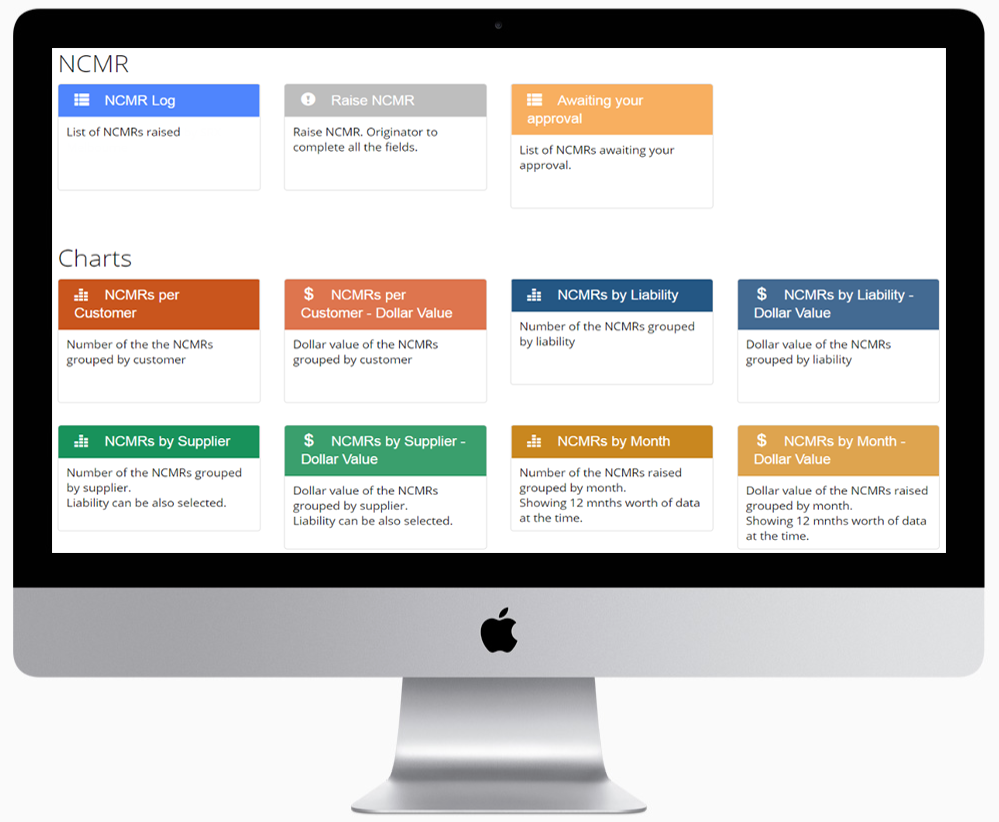

Product Screenshots

Click any image to enlarge

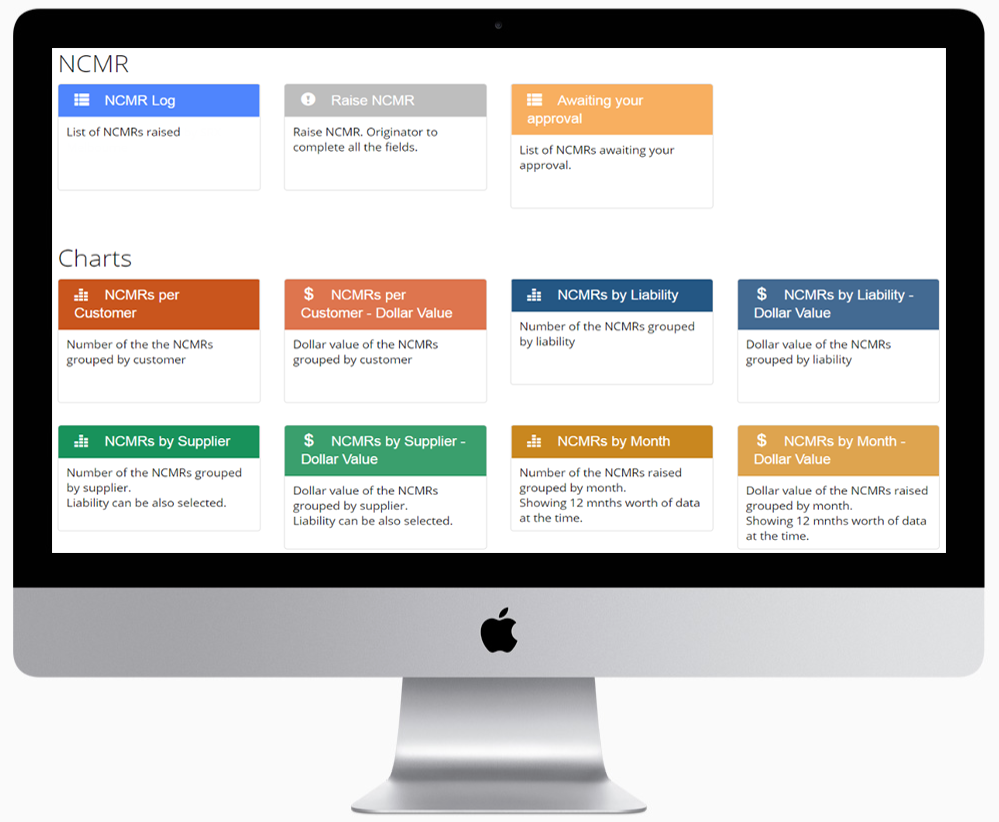

Reduce waste and improve quality with comprehensive non-conformance tracking. Log NCMRs instantly, analyse root causes, and make data-driven decisions to improve supplier performance.

Every non-conformance that goes untracked is money lost. NS-NCMR makes it easy to log issues from the production floor, notify the right people immediately, and build a database of quality data that drives continuous improvement.

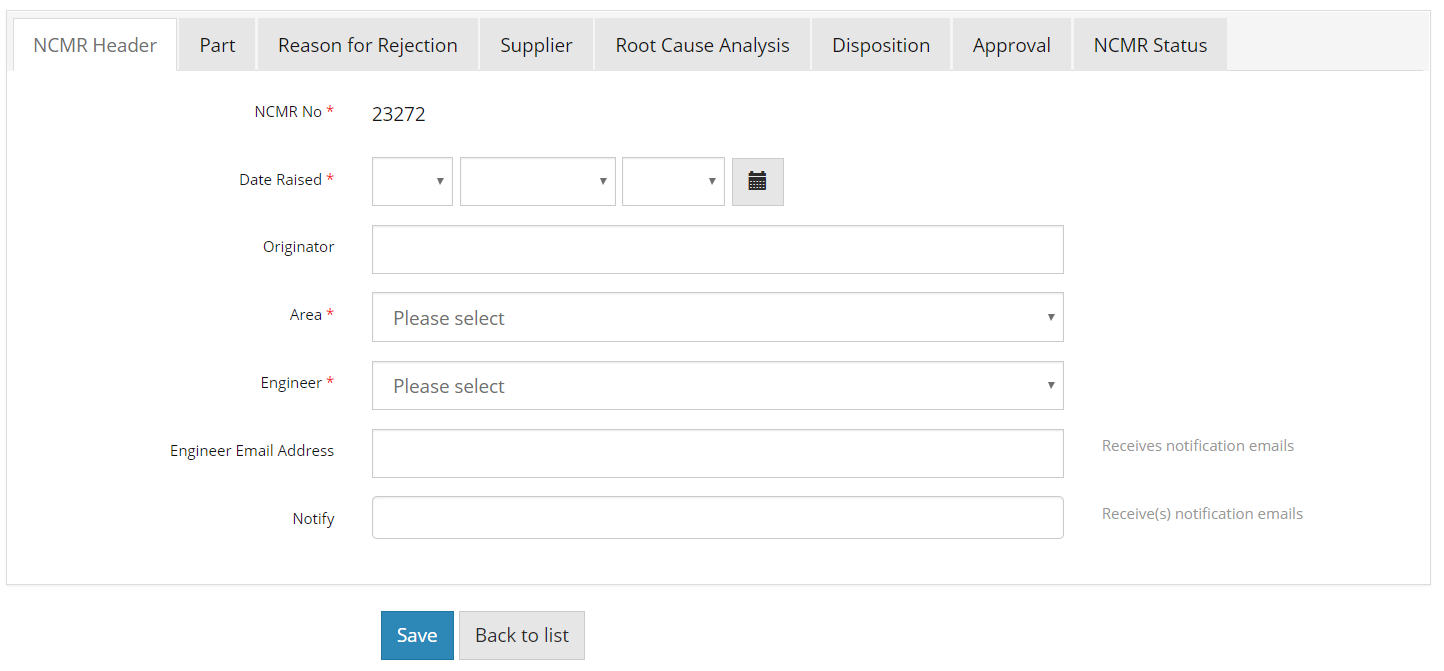

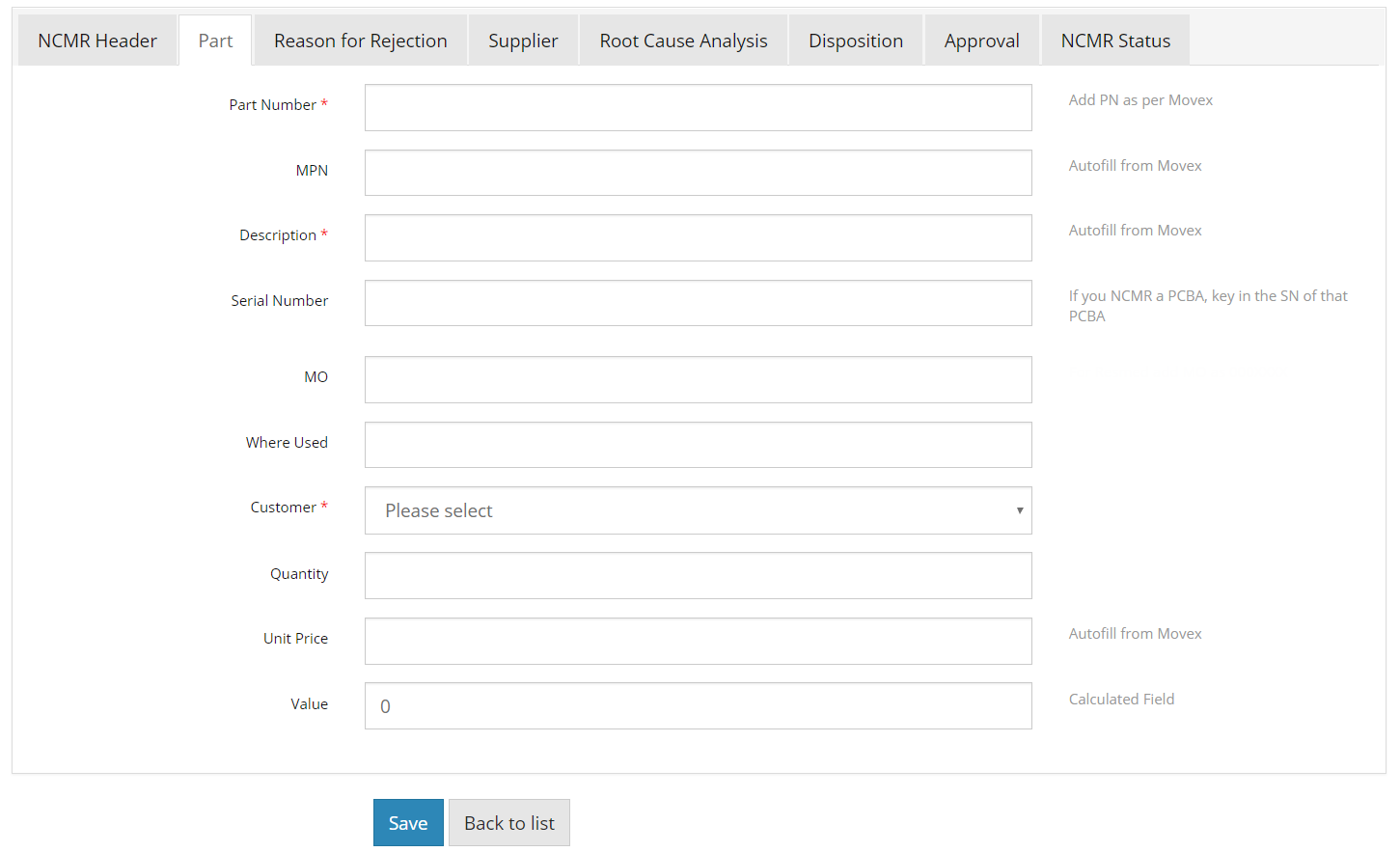

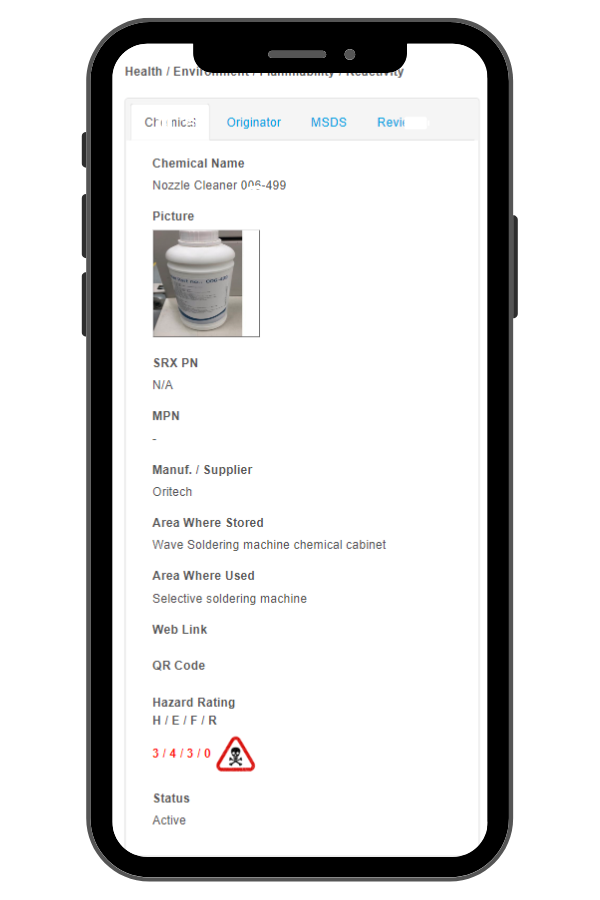

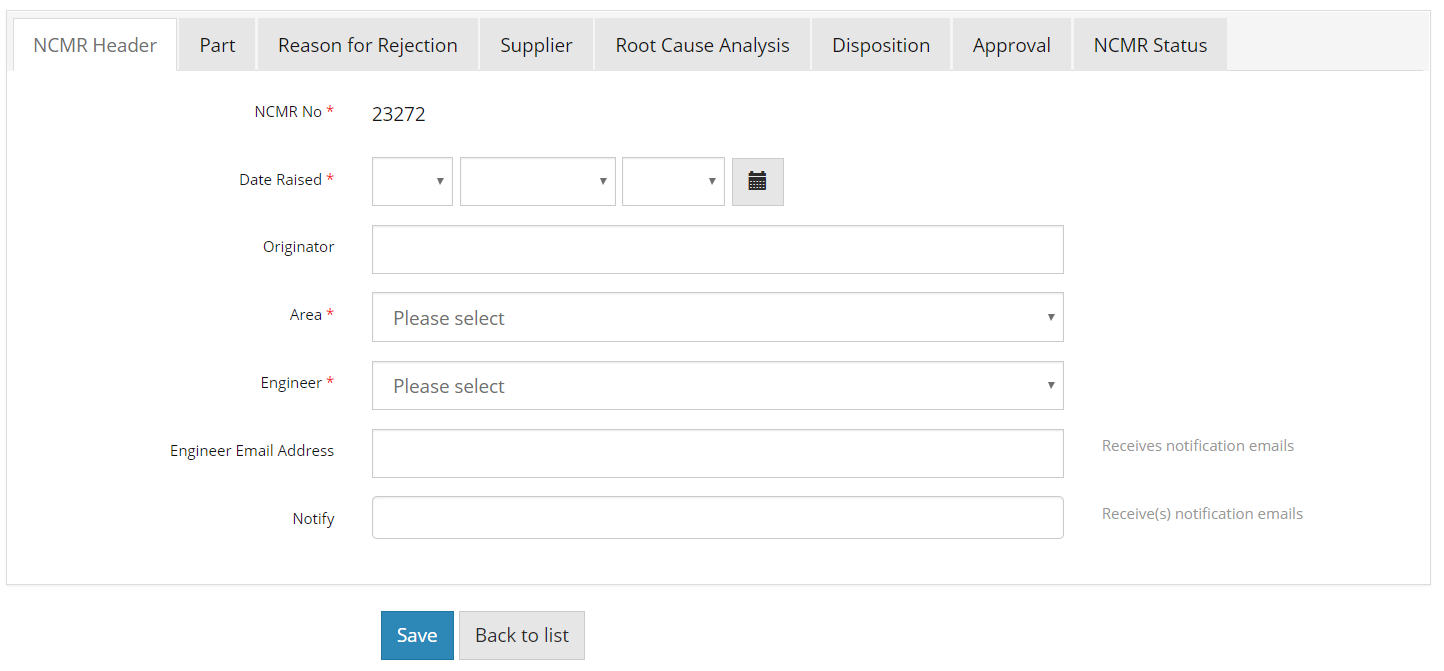

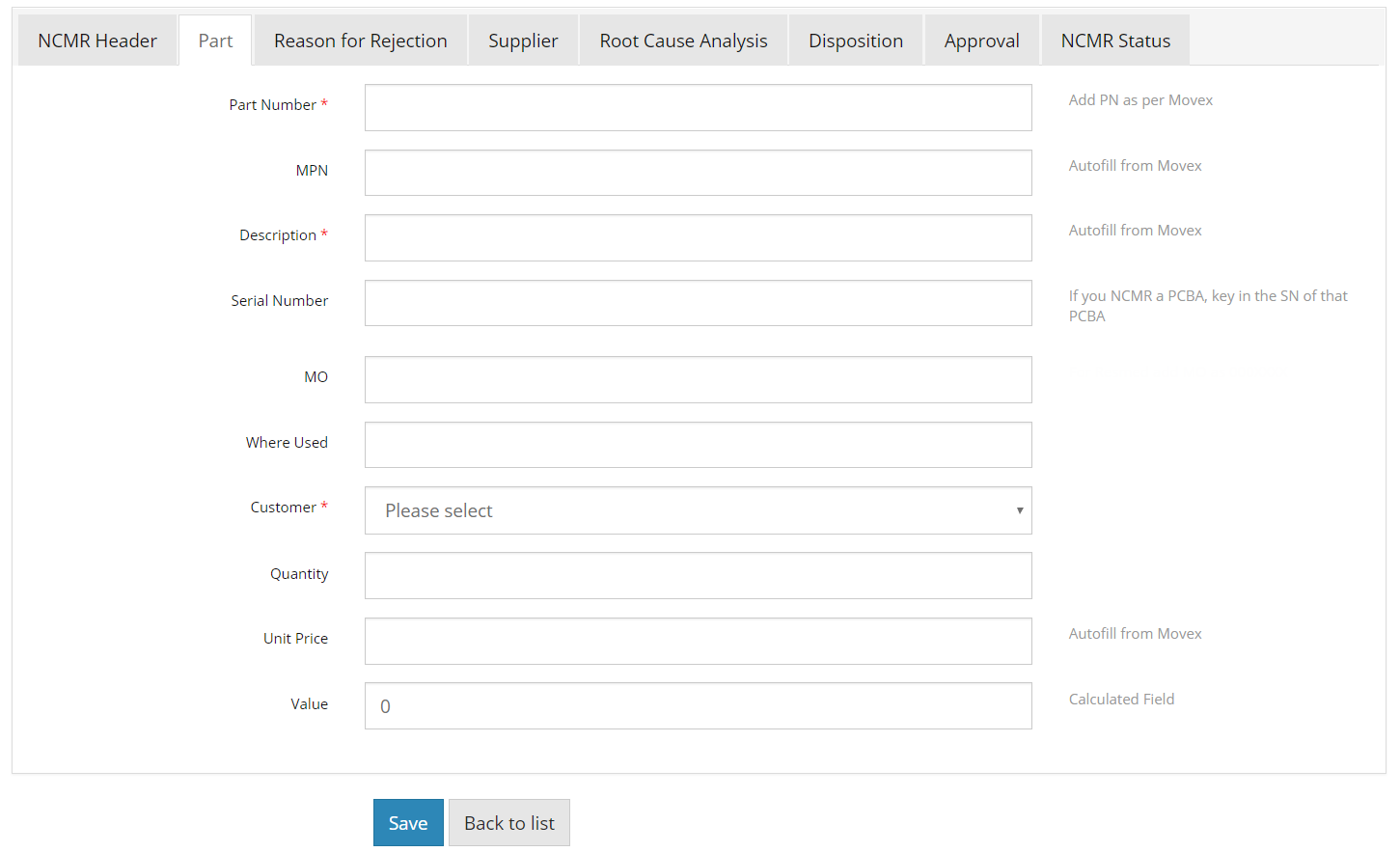

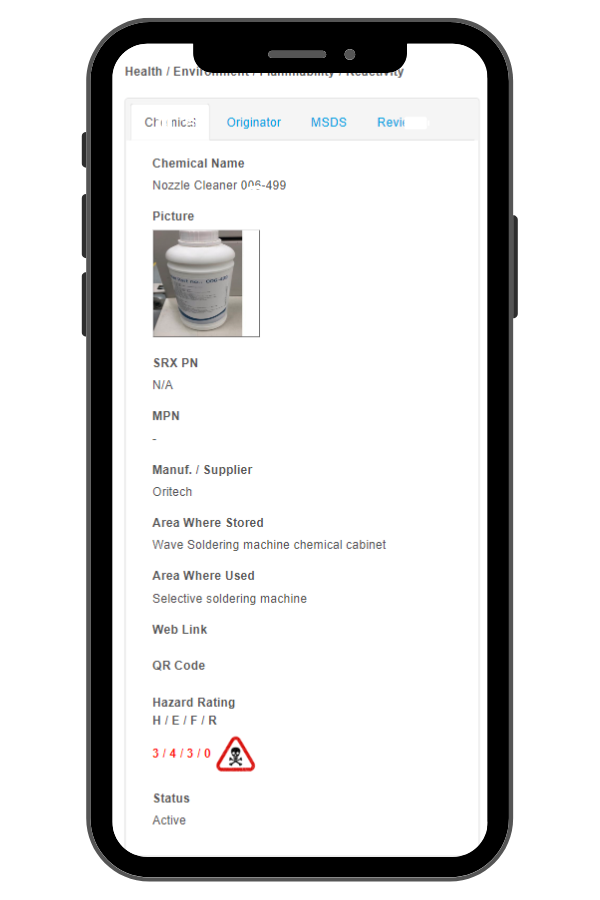

Log non-conformances with description, part numbers, quantities, photos, and affected batch information.

SMS and email alerts to SQE, Engineering, and Quality teams within seconds of logging.

Standardised root cause categories make analysis consistent and enable meaningful trending.

Track disposition decisions: Scrap, Rework, Use-As-Is, or Return to Supplier with full audit trail.

Track rework costs, scrap value, and supplier charge-backs. Know your true Cost of Quality.

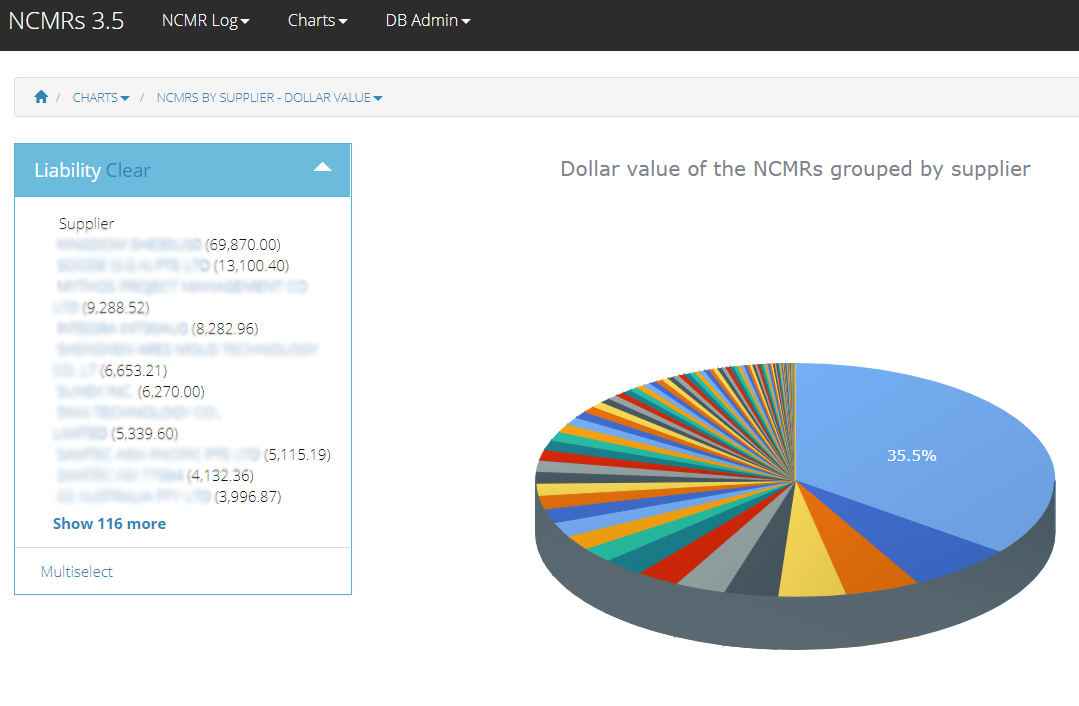

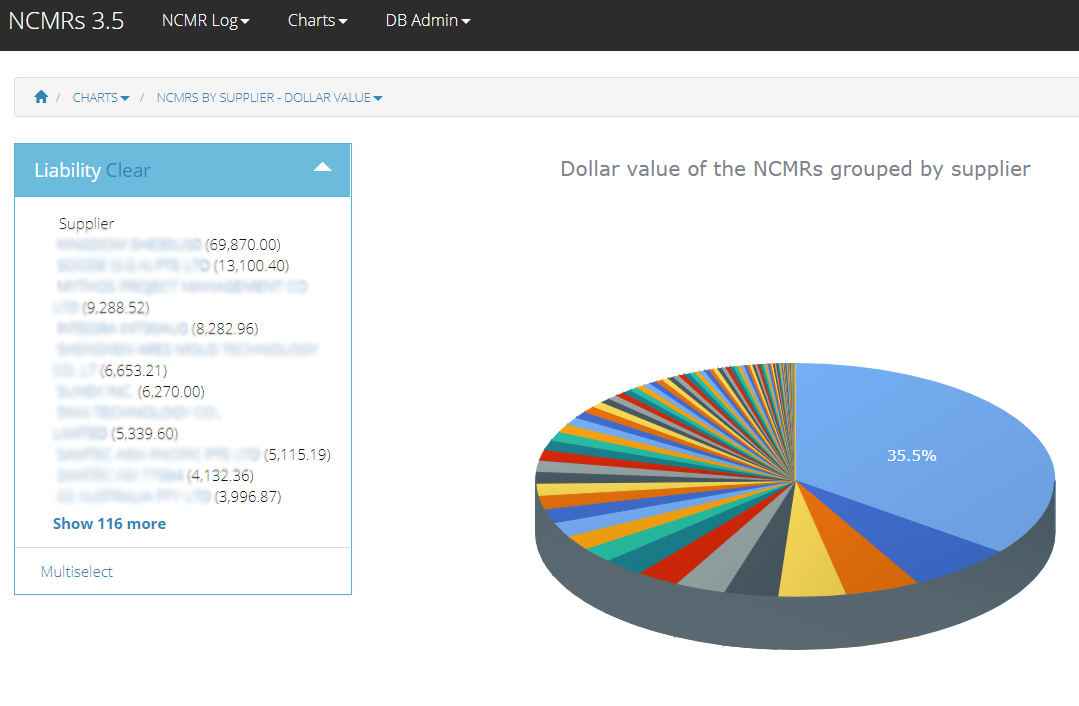

Pareto charts, trend analysis, supplier scorecards, and Cost of Quality dashboards.

Click any image to enlarge

Operator discovers non-conforming material

Create NCMR with photos and details

SQE analyses root cause

Decide: Scrap, Rework, or Return

Document resolution and costs

NS-NCMR supports your ISO 9001 quality management system with proper documentation and audit trails.

Track count and value by supplier. Identify your problem vendors.

See which customer orders are affected. Manage relationships proactively.

Track NCMRs over time. See if you're improving or getting worse.

Find the vital few. Focus on the 20% causing 80% of your problems.

Know your scrap, rework, and return costs. Make the business case for improvement.

Rate suppliers on quality performance. Drive accountability.

Every untracked non-conformance is a missed opportunity to improve. Start building your quality database today.