Your Testers Generate Gigabytes of Data. Are You Using It?

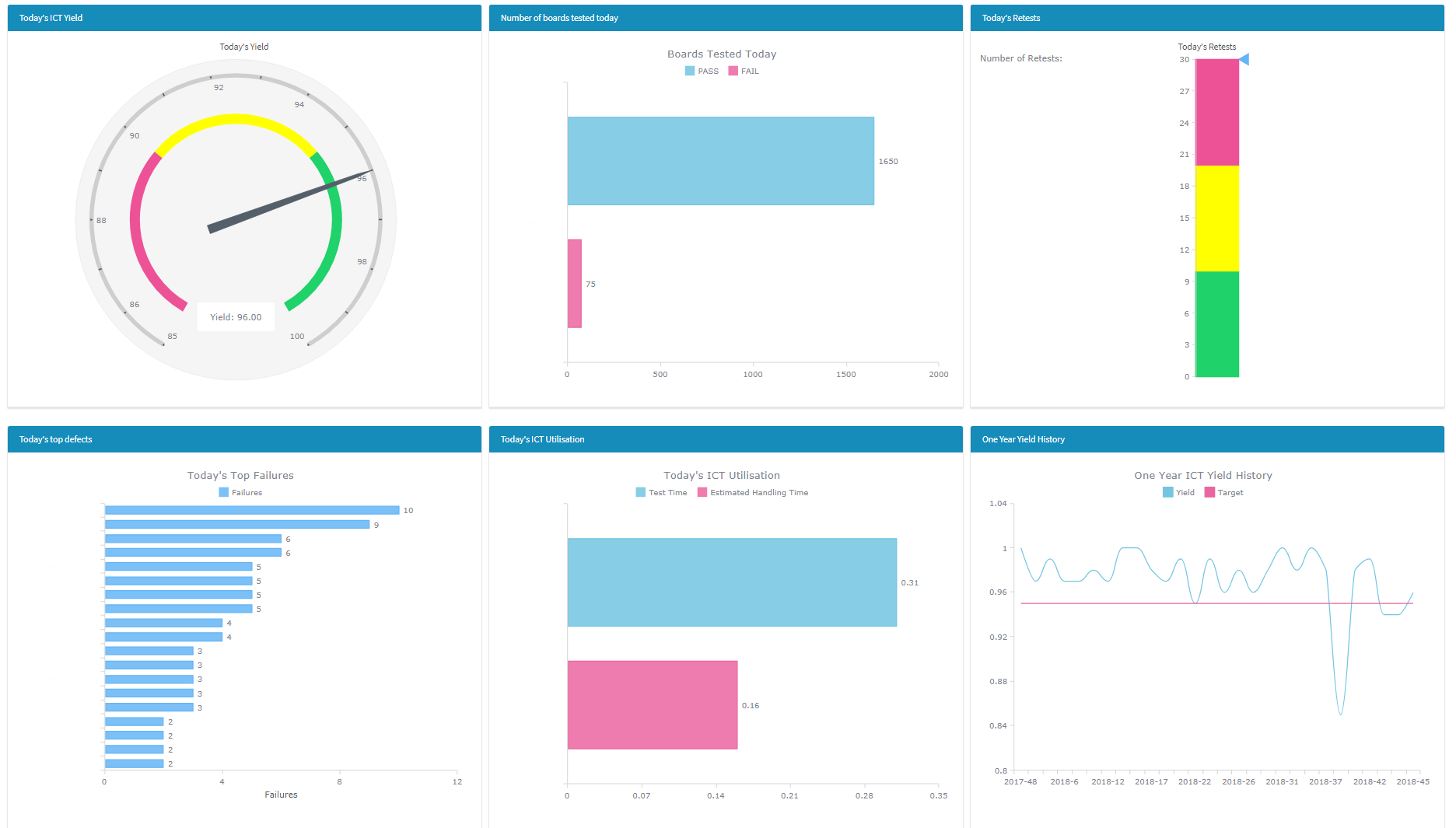

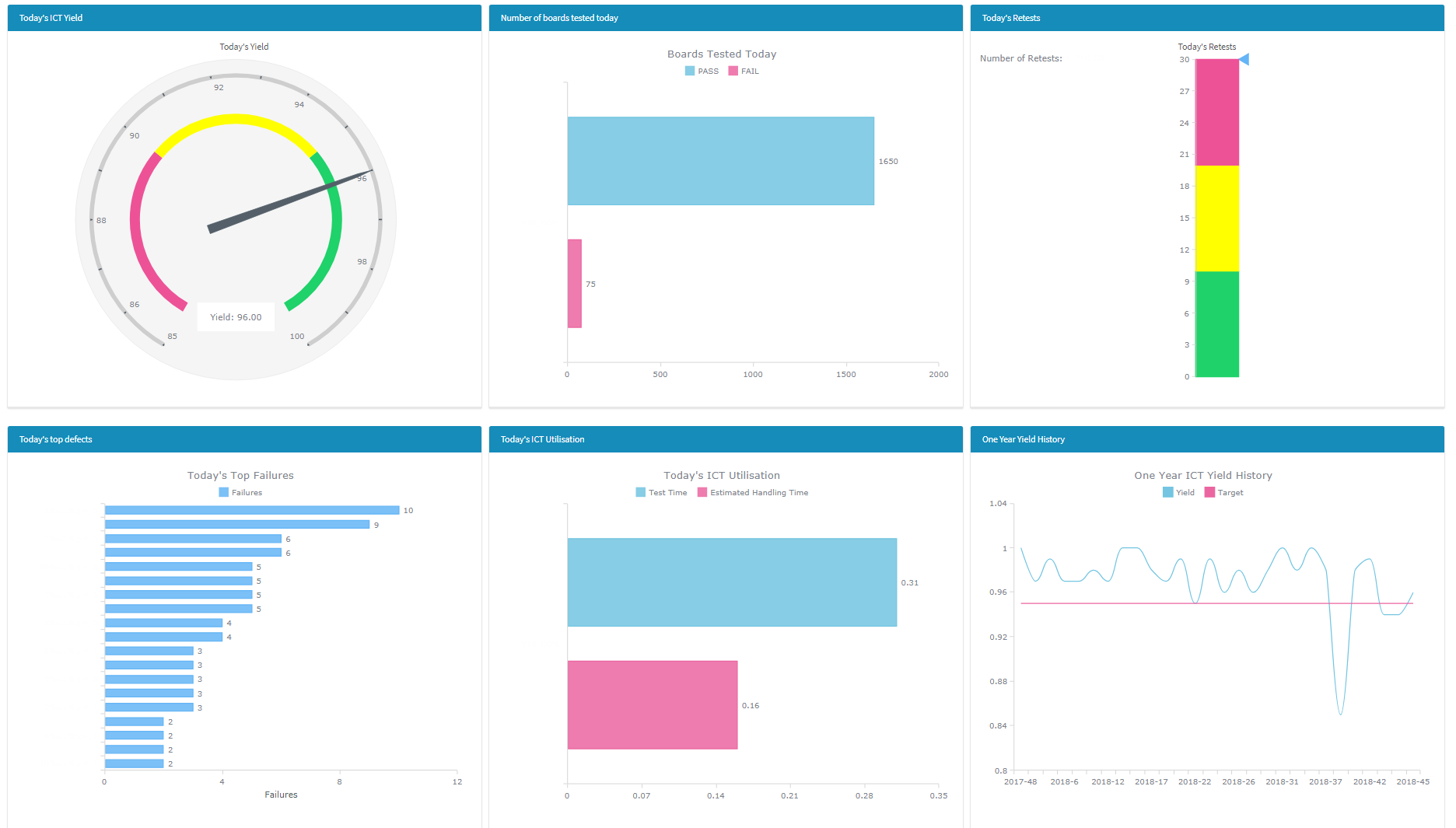

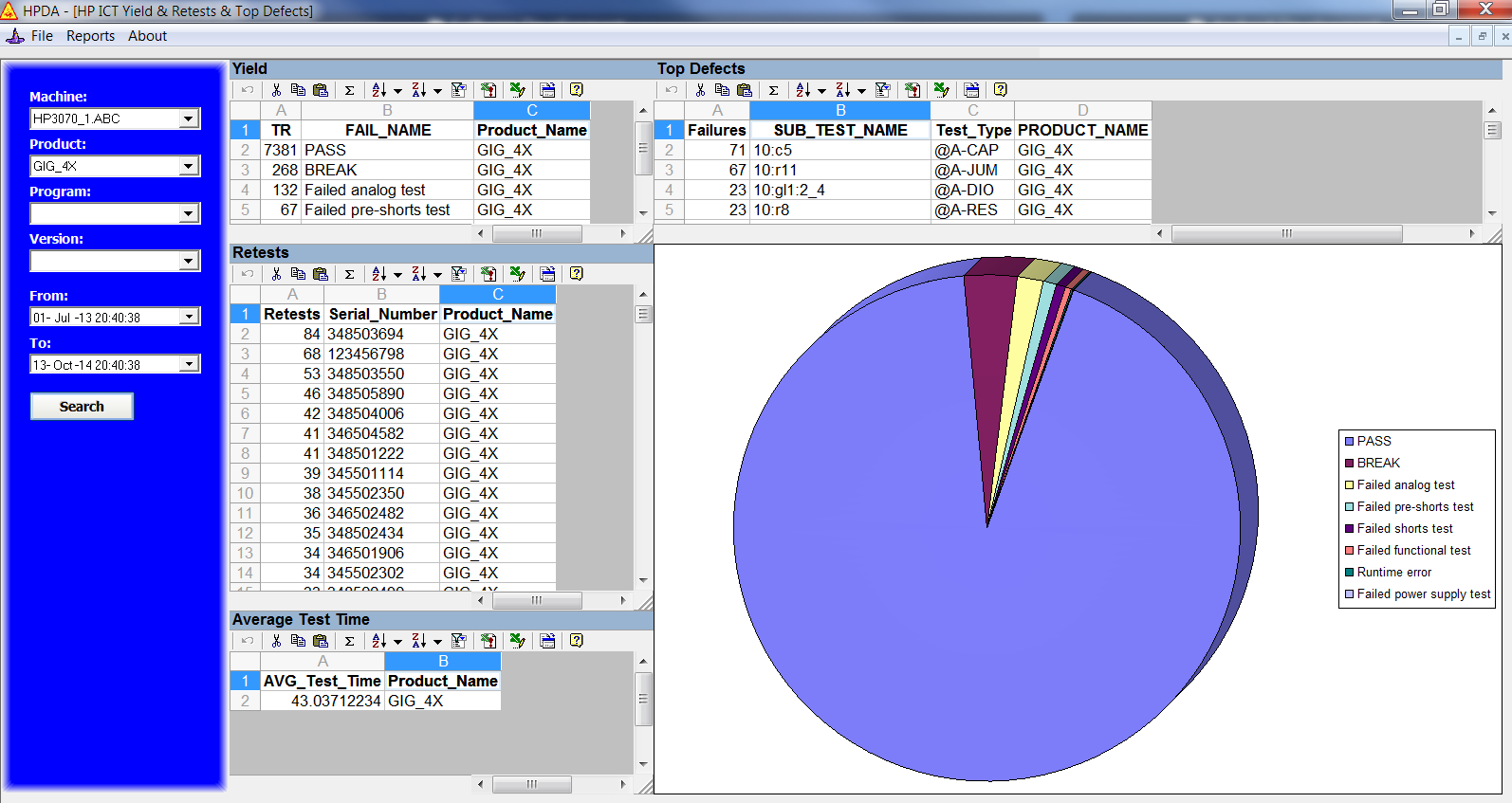

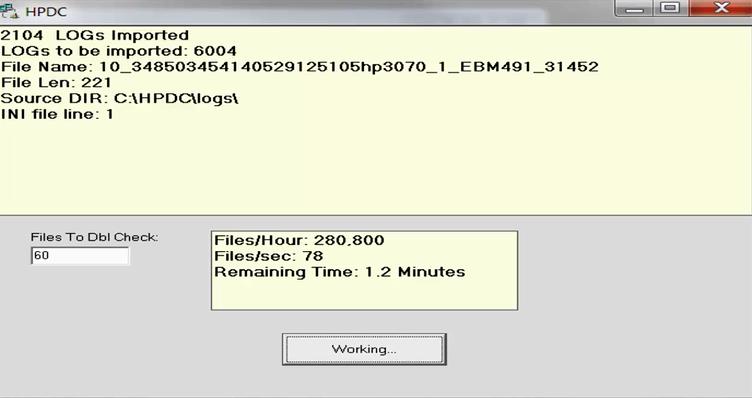

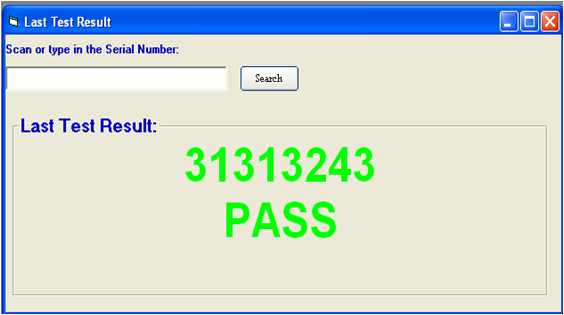

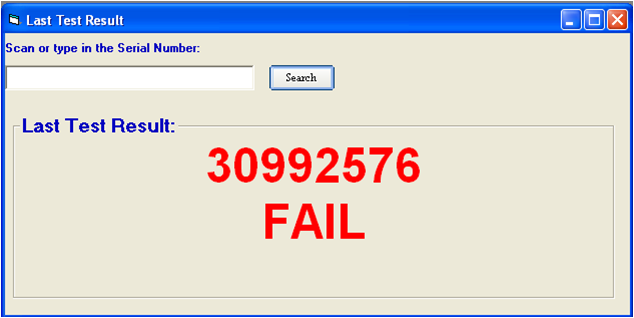

Most EMS companies collect test logs but struggle to extract value from them. NS-HPDCA bridges that gap — automatically parsing log files, storing results in a structured database, and delivering real-time visibility into what's happening on your test floor.

- See yields in real-time — No more waiting for end-of-shift reports

- Catch problems early — Anomaly detection alerts you to yield drops instantly

- Reduce debug time — Drill down to specific failures by board, component, or time

- Prevent escapes — FQC quality gate stops failed units from shipping

- Make data-driven decisions — Historical trends inform process improvements