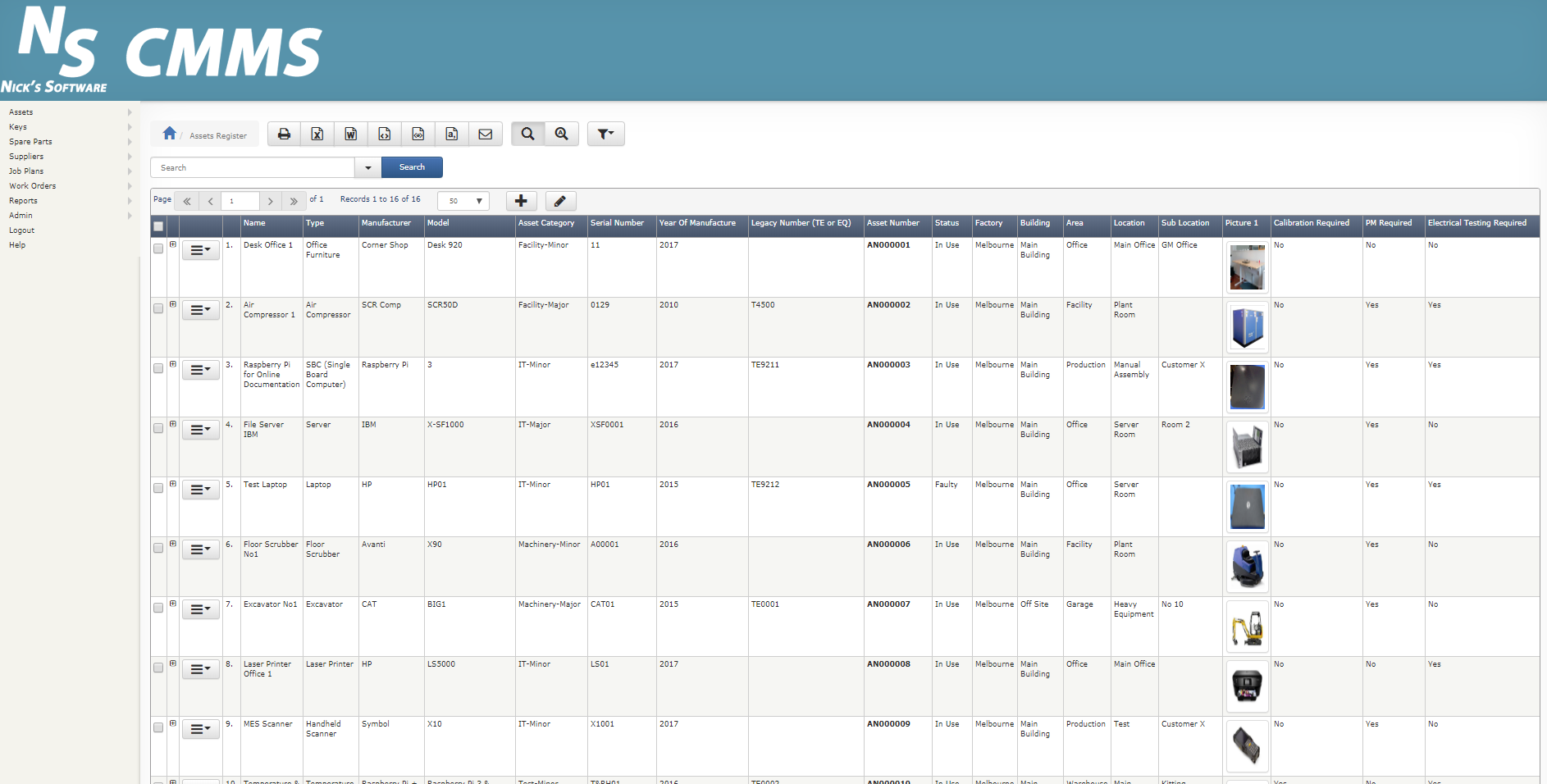

30+ powerful Reports, Charts and Dashboards

- Gain insights with interactive visualizations: Data is powerful, but raw numbers can be overwhelming. NS-CMMS brings your data to life with interactive charts and graphs. Easily identify trends, patterns, and outliers to understand the bigger picture of your maintenance operation.

- Drill down for deeper understanding: Don't get stuck at surface level. NS-CMMS allows you to drill down into specific data points for a more granular analysis. For example, if a report reveals high downtime for a specific equipment type, you can easily drill down to see the work orders associated with that equipment and identify recurring issues.

- Improved communication and collaboration: Share reports with ease! NS-CMMS allows you to export reports in various formats, like PDF and CSV, for easy distribution to stakeholders across your organization. This fosters transparency and collaboration, enabling teams to work together towards shared maintenance goals.

- Make informed decisions with confidence: Data-driven decision making is crucial for effective maintenance. With NS-CMMS reporting, you have the insights you need to prioritize maintenance tasks, allocate resources efficiently, and identify areas for improvement.